Brass finishings

A unique metal

All lamps are made of brass, a copper-based alloy, ideal for creating the most beautiful metal objects. Since the Bronze Age, this yellow metal has never ceased to fascinate, not only because of its color, but also because of the subtlety of its transformation and the variety of applications it offers. It is an added value in itself.

The experience of our employees has taught us a love and passion for this metal, and each element of a luminaire is made by hand. The whole company shares the traditional values that transform and embellish this metal: from cutting to threading, from turning to tapping, from embossing to welding, from patina to any other finish. Each step gives our lighting fixtures a precision and "top of the range" quality, far superior to any other "industrial" production.

After obtaining the "brushed bronze" patina, manual drying in sawdust

Values and skills that we hold dear

People are at the heart of our company. The work in our workshops is traditional and conventional. The irreplaceable hands, the techniques learned by the elders and passed on to the young, and the skill of our loyal employees, sublimate all materials with respect. This is reflected in the quality and precision of each of our creations.

Each component of our lighting fixtures is designed and manufactured by our craftsmen. It is a collection they are very proud of. These are just a few of the skills that form the basis of our Lighting Collection.

Various metal finishes

The Lighting Collection offers a wide range of metal finishes: bronze, satin brass, nickel, chrome or white and structured black. The Lighting Collection owes its reputation in this field to a few teams of craftsmen who are particularly skilled in the execution of these beautiful finishes.

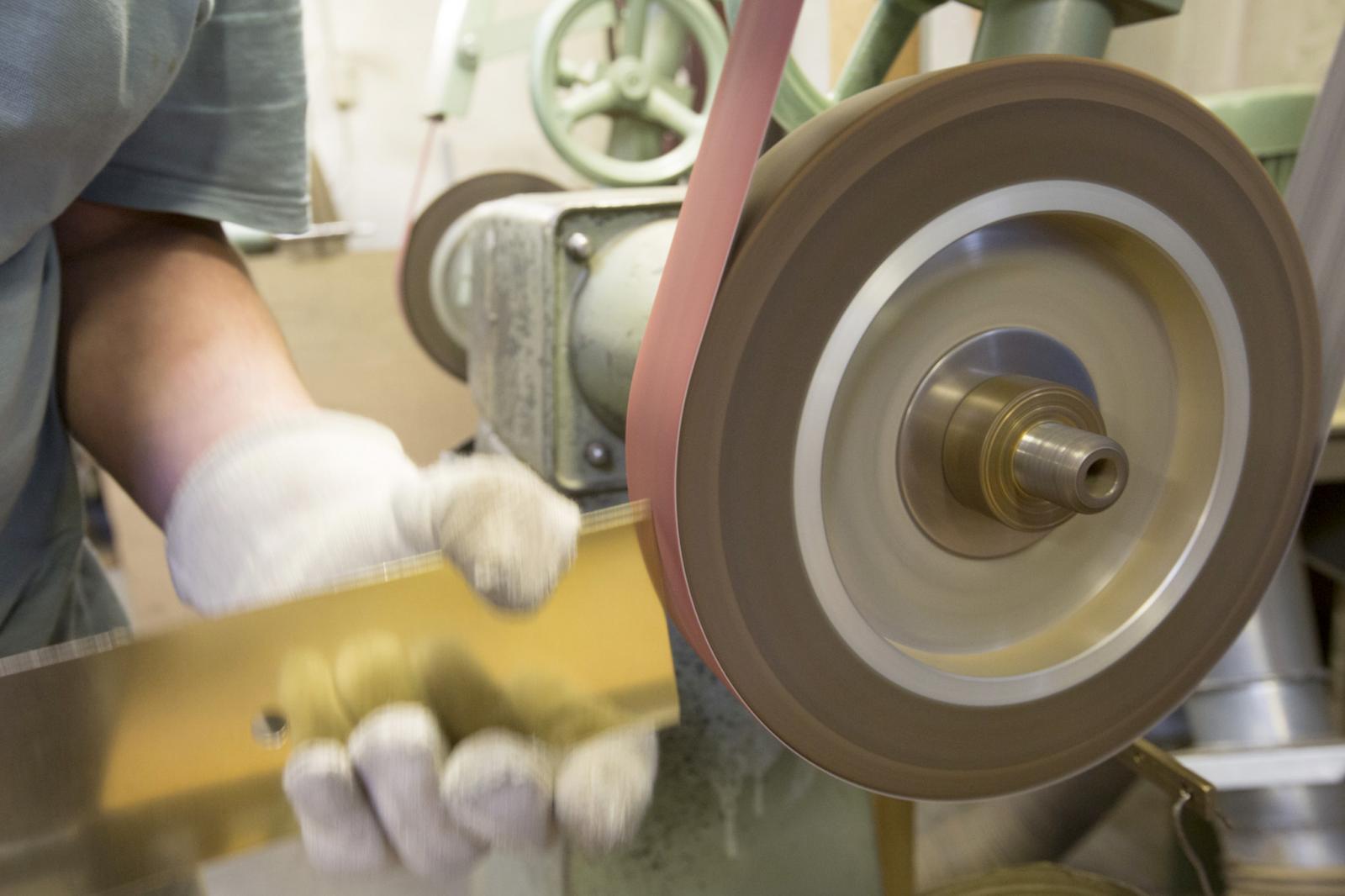

Prior to the application of the finish, all metal parts of our luminaires are prepared by the polisher. He will start by sanding with an abrasive belt to remove all manufacturing scratches and excess silver solder. To give them a matt appearance, he will brush them with a rotating brush.

Sanding with an abrasive belt, to remove all the manufacturing scratches and the excess of silver brazing

Next, a team of bronziers applies the different patinas on the brass: brushed bronze, light bronze or medal bronze. By electrolysis, chrome or nickel is deposited on the brass.

Manual stripping of the brass with a degreasing powder

Bronze patina begins to settle on the brass

To obtain a mirror-polished appearance, the polisher polishes on a cloth pad placed on a lathe at very high speed (3,000 rpm). The pad is coated with a special paste, the high speed and the heat generated give the brass a smooth, bright and shiny finish.

Polishing the brass on a buffer at 3,000 rpm to a mirror-like, shiny finish

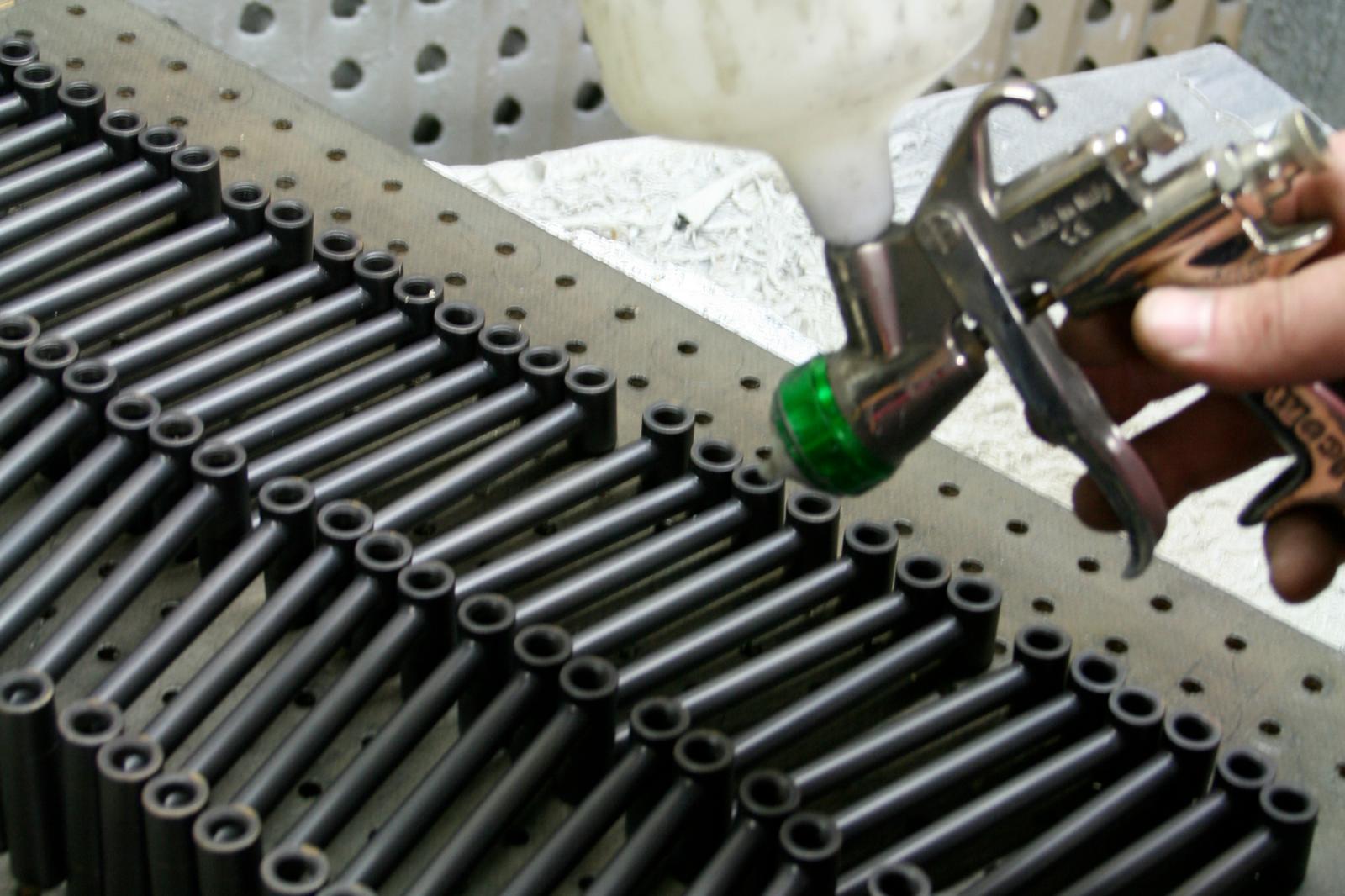

The varnisher finishes all brass parts with a protective varnish to preserve them from oxidation.

Protective varnish sprayed on articulated arms to protect them from oxidation

You can discover these techniques in the video shot in our workshops and online on our homepage.